A Wright Method and the Chart Blending Method Provides Cold-Cranking Simulator (CCS) and Mini- Rotary Viscometer (MRV) viscosity calculations Calculates conversions between centistokes and Saybolt or Krebs units Enables VI calculations from kinematic viscosity measurements at any two temperatures Generates kinematic viscosity interpolation reports, and displays SAE and ISO VG Lubricant Specifications tables Provides an interface for analysis of Cold-Cranking Simulator and Mini-Rotary Viscometer data Provides temperature probe constant calculations. Performs oil blending calculations using the W. The viscosity index according to DIN 2909 is calculated by comparing the change in viscosity of an oil with the two oils as a reference. The version 2 release of VISDISK has added a graphing capability and an NBS “best-fit” computation that analyzes multiple kinematic viscosity data points and selects the optimum viscosity curve for the sample data provided. Test data can also be used to generate a complete interpolation report at temperature increments specified by the user. An interpolation component calculates viscosity at any specified temperature or temperature at a desired viscosity.

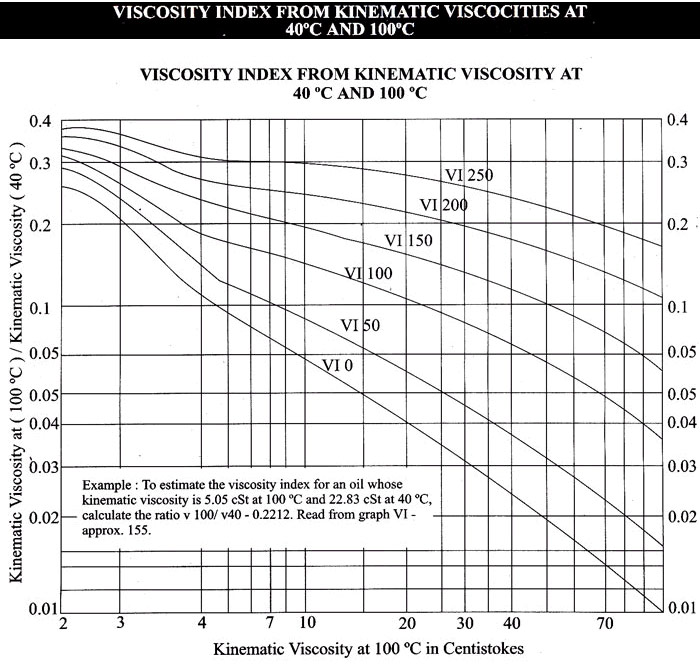

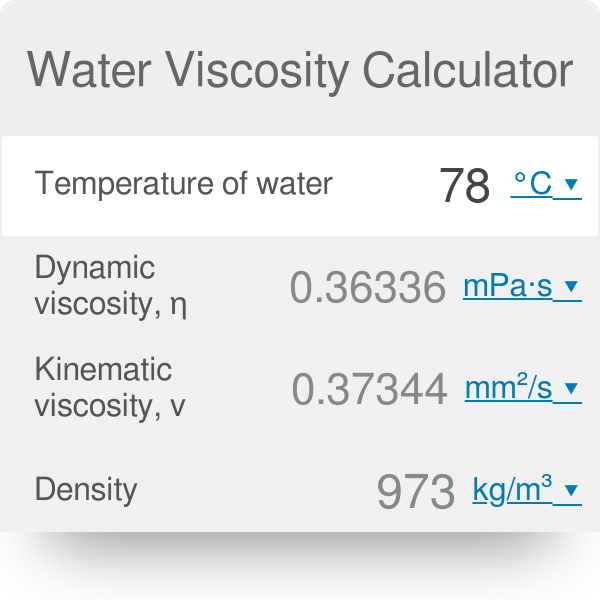

VISDISK facilitates calculation/verification of kinematic viscosity by providing a data table for input, and then performing complex viscosity and density calculations. VISDISK also provides supporting data analysis capability for several equipment items manufactured by CANNON, including the PolyVISC, Cold-Cranking Simulator (CCS), Bending-Beam Rheometer, and the CANNON Mini-Rotary Viscometer (CMRV). Viscosity decreases as temperature increases because the molecules vibrate more, and interact less.The VISDISK program brings computerized solutions to many difficult computational problems associated with kinematic viscosity determination. The viscosity of coconut oil is dependent upon temperature. The results obtained from the calculation of VI from kinematic viscosities determined at 40 and 100C are virtually the same as those obtained from. The viscosity-temperature coefficient for coconut oil can vary by a factor of 10 depending on the temperature. The viscosity index obtained by the graphical method is much higher than that obtained by the other methods. Viscosity index obtained with the calculator program is 99,39% lower than that obtained by equation (1). The measurements were carried out at 40± 0.1 and 100± 0.1☌, according to the recommendation of ASTM D2270. Viscosity index of a coconut oil was determined using a set of Schott Ubbelohde-type viscometers selected according to the values of their constants, so that the margins of the uncertainty, inherent in the Hagebach-Couette correction, does not exceed the error allowed for the measurements. that involve the calculation of viscosity blending index, show general.

The viscosity-temperature coefficient was calculated from the measured viscosity at 40☌ and 100☌. Viscosity and density are the most important parameters since the oil needs to. Viscosity index calculation was performed with a computer program using kinematics viscosity at 40☌ and 100☌. Viscosity index was calculated from the measured viscosity at 40☌ and 100☌ using ASTM Method D 2270 and was graphically determined using ASTM D 341. In this paper viscosity index of coconut oil was determined using three methods.

0 kommentar(er)

0 kommentar(er)